Sustainable specification is not a new concept. We are all familiar with the practice of ensuring that any timber products included in a specification are sustainably sourced, with full traceability back to a managed forest. Yet, sadly, the same responsibility is rarely applied when it comes to the specification of plastic products. It’s time for architects and specifiers to place more emphasis on the origins of the plastic products in their specification, to help reduce waste and lower the carbon impact of our buildings.

The need for change

More than a third of the UK’s annual waste comes from the construction sector alone, of which 25 million tonnes is disposed at landfill. The UK construction sector is the largest consumer of natural resources and it is clear that something needs to change. In any strategy that looks to reduce environmental impact, it is vital to consider how construction materials are disposed of and which products are being specified for new builds.

The recycling and reuse of materials has an important role to play in lowering the environmental impact of buildings and achieving a net-zero carbon footprint. Moreover, with the latest law to reduce carbon emission by 78% by 2035 in accordance with the Paris Agreement, it is likely, not long before the construction industry is called on to introduce further measures to reduce its impact.

What are we doing?

We are constantly looking to improve our own impact within the supply chain. Over 25 years ago, we changed our processes to start using recycled material originating from PVC-U windows in manufacturing our PVC-U products. Since then, we have continued to invest in research and development to refine this process so that we can offer PVC-U products that contain higher amounts of recycled material. In 2020, this figure reached an average of 74% across our range. Not only that, all white Marshall-Tufflex conduit, mini and maxi trunking lengths are currently manufactured using 100% recycled material.

The business uses a compounder machine – a powerful piece of equipment that can process both post-industrial waste (off-cuts from PVC-U window production) and post-consumer waste (from PVC-U windows removed from buildings at the end of their lives). The PVC-U is granulated and processed through the compounder to remove any impurities, resulting in recycled PVC-U material that will be used for new trunking or conduit systems.

What’s more, the use of waste PVC-U windows improves our carbon footprint. Research from the Sustainable Industrial Systems group at the University of Manchester found that a PVC-U window manufactured using recycled content has between 17 and 20 times less embodied carbon than those manufactured from virgin plastic.

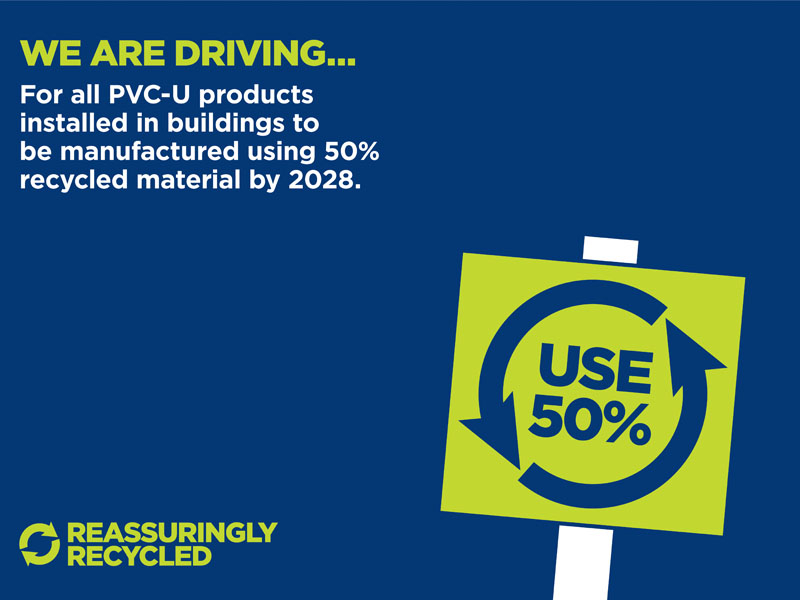

It is our goal that all PVC-U cable management products installed in buildings are manufactured using recycled material by 2028. But this requires support from everyone across every level of the electrical industry. Architects and specifiers have a significant influence to drive demand and if PVC-U trunking solutions that are made with a minimum of 50% recycled plastic are more commonly specified, then the hope is that other manufacturers, and indeed, the industry, will follow.

Green does not mean grey

Unfortunately, materials manufactured from recycled plastics often have a stigma attached and are perhaps perceived as lower quality with concerns around colour consistency. However, this is not the case with our products. To ensure consistent quality across all of our products, material samples from the production line are taken every hour to check for consistency in colour and surface finish. Further still, the durability of PVC-U plastic from recycled windows is incredibly strong as it is designed to withstand extreme external weather elements.

It is clear that there are huge benefits to writing tighter specifications for plastic products where possible. While we at Marshall-Tufflex have started to instigate change in the cable management industry, it is also the job of architects and specifiers to drive for change in all levels of construction by specifying products manufactured using more sustainable materials. Afterall, if the price point is the same and the quality is better, why wouldn’t you specify products with lower environmental impact?